Waterproof PU Belt: The Ideal Accessory for the Food Industry

Introduction

Belts are an essential accessory in our daily lives, serving both functional and aesthetic purposes. However, when it comes to specific industries such as the food industry, ordinary belts may not always suffice. That's where waterproof PU (Polyurethane) belts come into play. In this article, we will explore the importance of waterproof PU belts, their key differences from ordinary belts, and how they are ideal for use in the food industry.

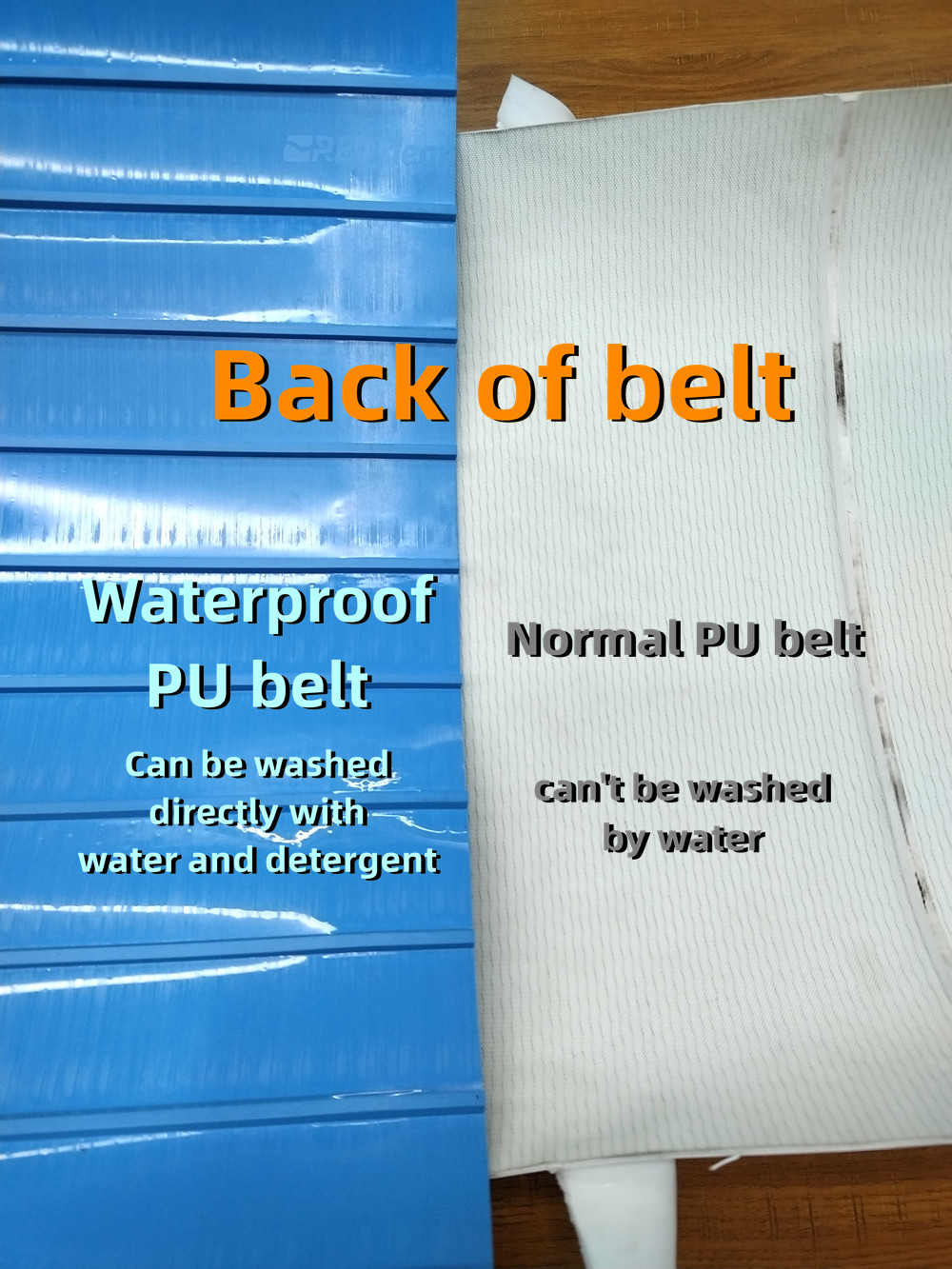

- The Difference with Ordinary Belts

Waterproof PU belts are specifically designed to withstand harsh environments, offering numerous advantages over ordinary belts. Let's delve into some key differences:

1.1 Enhanced Water Resistance

Unlike ordinary belts, which may become damaged or degraded when exposed to moisture, waterproof PU belts are specifically engineered to be water-resistant. This means they can withstand direct contact with water, making them ideal for applications where liquids or humidity are present.

1.2 Durability and Longevity

Waterproof PU belts are crafted from high-quality materials that are known for their durability. They exhibit excellent resistance to wear and tear, ensuring a longer lifespan compared to ordinary belts. This enhanced durability translates to reduced maintenance costs and increased productivity in industrial settings.

1.3 Chemical Resistance

Another significant advantage of waterproof PU belts is their resistance to various chemicals. In the food industry, where contact with food substances, cleaning agents, and disinfectants is common, ordinary belts may degrade over time. Waterproof PU belts, on the other hand, are designed to withstand exposure to a wide range of chemicals, maintaining their integrity and performance.

1.4 Hygienic Properties

Maintaining hygiene standards is paramount in the food industry. Waterproof PU belts are easy to clean and disinfect due to their non-porous surfaces. They prevent the accumulation of dirt, moisture, and food particles, reducing the risk of contamination. This feature is crucial for compliance with food safety regulations and ensuring the production of safe, high-quality food products.

- Ideal for Use in the Food Industry

The food industry demands rigorous hygiene standards and compliance with strict regulations. Waterproof PU belts offer unique advantages that make them the ideal choice for this sector.

2.1 FDA Compliance

The U.S. Food and Drug Administration (FDA) has stringent regulations regarding materials that come into contact with food. Waterproof PU belts are designed to meet these regulations, ensuring they are safe for direct or indirect contact with food products. This compliance makes them an optimal choice for food processing, packaging, and handling applications.

2.2 Water and Humidity Resistance

Food processing environments often involve the use of water, liquids, and high humidity levels. Waterproof PU belts excel in such conditions, as they are impervious to water absorption and humidity-induced swelling. This quality ensures that the belts retain their mechanical strength, preventing any disruption to the production process.

2.3 High-Temperature Resistance

Certain food production processes require exposure to high temperatures, such as baking or cooking. Waterproof PU belts are designed to withstand these extreme temperatures without compromising their structural integrity. Their heat resistance properties make them suitable for use in ovens, grills, and other heat-intensive food processing applications.

2.4 Non-Toxicity and Odorlessness

When it comes to food contact materials, ensuring the absence of toxic substances or unwanted odors is crucial. Waterproof PU belts are manufactured using food-grade materials that are non-toxic and odorless, ensuring the highest standards of food safety and consumer satisfaction.

Conclusion

Waterproof PU belts offer distinct advantages over ordinary belts, making them a preferred choice for industries such as the food industry. Their enhanced water resistance, durability, chemical resistance, and hygienic properties set them apart. With FDA compliance, resistance to water, humidity, and high temperatures, as well as non-toxicity and odorlessness, waterproof PU belts fulfill the stringent requirements of the food industry.

Investing in waterproof PU belts not only ensures compliance with food safety regulations but also contributes to enhanced productivity, reduced maintenance costs, and improved product quality. With their exceptional performance and reliability, waterproof PU belts continue to revolutionize the food industry, providing a reliable and hygienic solution for various applications.