The Ultimate Guide to Continuous Bucket Conveyor

Learn everything you need to know about continuous bucket conveyor systems, from how they work to design considerations and safety guidelines.

How does a continuous bucket conveyor work?

The buckets on the conveyor system are designed to scoop up materials and transport them along the conveyor. As the chain or belt moves, the buckets are filled and then emptied at the discharge point. The empty buckets then return to the start of the conveyor to scoop up more material.

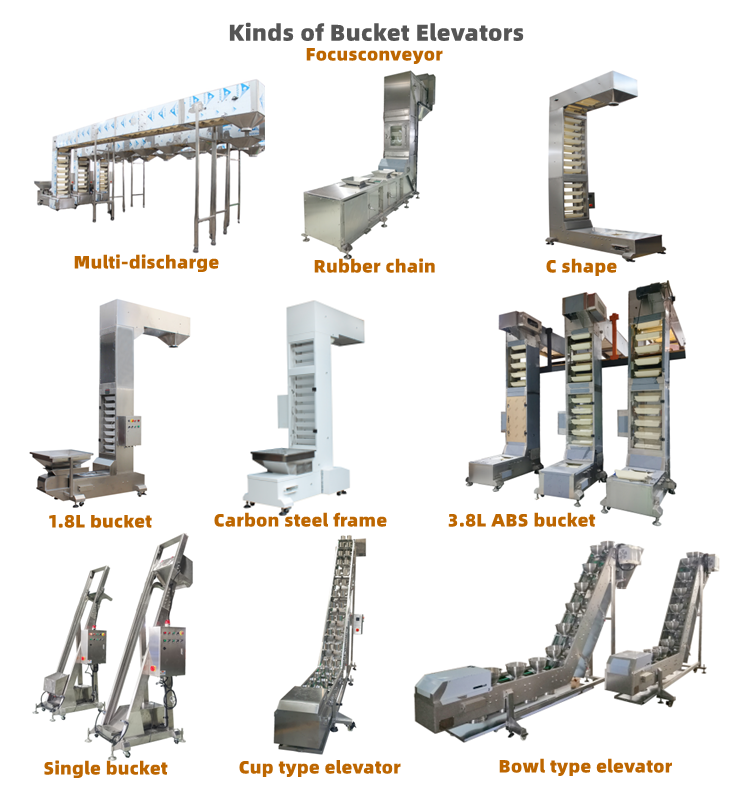

Types of continuous bucket conveyor

There are two main types of continuous bucket conveyors: chain bucket conveyors and belt bucket conveyors. Chain bucket conveyors are ideal for heavy-duty applications and can handle a wide variety of materials, including abrasive and hot materials. Belt bucket conveyors, on the other hand, are better suited for lighter loads and are commonly used in the food and pharmaceutical industries.

Designing an effective continuous bucket conveyor system requires considering several factors, such as:

Operating a continuous bucket conveyor system safely requires following strict guidelines and procedures. Some safety considerations include:

In conclusion, continuous bucket conveyor systems are essential material handling tools that offer many advantages for various industries. With proper design, maintenance, and safety measures, these systems can help improve efficiency, reduce labor costs, and ensure safe and reliable operation.

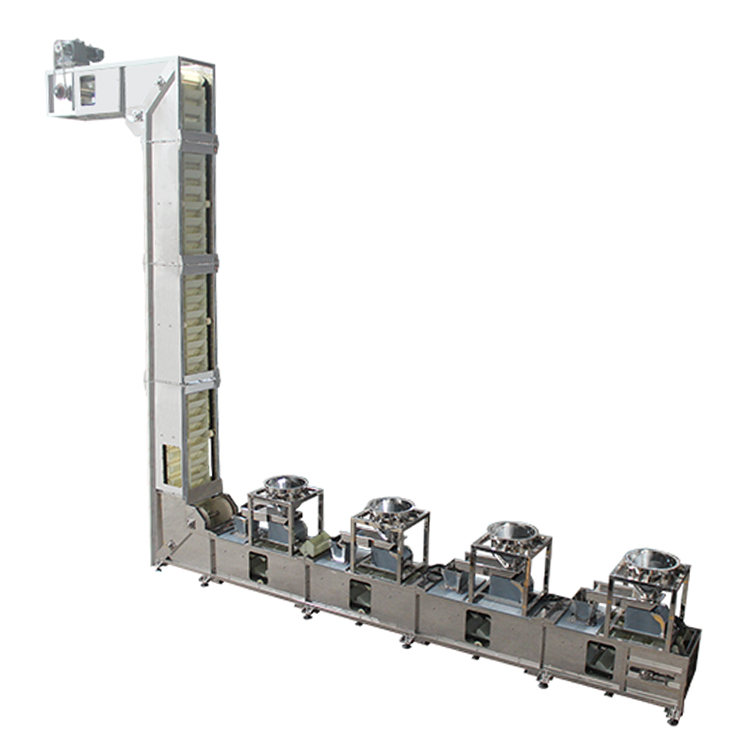

What is a continuous bucket conveyor?

A continuous bucket conveyor is a type of conveyor system used for material handling. It consists of a series of buckets attached to a chain or belt that moves continuously to transport materials vertically or horizontally.How does a continuous bucket conveyor work?

The buckets on the conveyor system are designed to scoop up materials and transport them along the conveyor. As the chain or belt moves, the buckets are filled and then emptied at the discharge point. The empty buckets then return to the start of the conveyor to scoop up more material.

Types of continuous bucket conveyor

There are two main types of continuous bucket conveyors: chain bucket conveyors and belt bucket conveyors. Chain bucket conveyors are ideal for heavy-duty applications and can handle a wide variety of materials, including abrasive and hot materials. Belt bucket conveyors, on the other hand, are better suited for lighter loads and are commonly used in the food and pharmaceutical industries.

Applications of continuous bucket conveyor

Continuous bucket conveyors are used in various industries for material handling. Some common applications include:- Bulk material handling in mining, construction, and cement industries

- Transporting food products in the food processing industry

- Moving pharmaceutical products into the pharmaceutical industry

- Moving fragile materials such as glass and ceramics into the manufacturing industry

- Handling waste materials in recycling plants

Advantages of continuous bucket conveyor

Using continuous bucket conveyor systems offers several advantages, such as:- Efficient and continuous material handling

- Reduced labor costs and improved worker safety

- Customizable to specific industry and application requirements

- Space-saving design that can be integrated into existing facilities

- Reduced material wastage and improved product quality

- Minimal maintenance is required for reliable operation

Factors to consider when selecting a continuous bucket conveyor system

Designing an effective continuous bucket conveyor system requires considering several factors, such as:

- The type of materials to be transported and their characteristics

- The required capacity and speed of the conveyor

- The layout and configuration of the system

- The discharge height and location

- The type of drive system and motor required

- The need for additional features such as sensors, alarms, and safety devices

Maintenance of continuous bucket conveyor

- Regular maintenance is essential to ensure the efficient and reliable operation of continuous bucket conveyor systems. Some maintenance tasks include:

- Regular cleaning to remove debris and prevent buildup

- Lubricating moving parts to prevent wear and tear

- Checking for loose or damaged components

- Replacing worn-out parts as needed

- Conducting regular inspections and preventive maintenance to identify potential issues before they become significant problems

Operating a continuous bucket conveyor system safely requires following strict guidelines and procedures. Some safety considerations include:

- Proper training of operators and maintenance personnel

- Ensuring guards and safety devices are installed and functioning correctly

- Conducting regular safety inspections and risk assessments

- Following lockout/tagout procedures when performing maintenance or repairs

- Using personal protective equipment such as gloves and eye protection when working with the conveyor system.

In conclusion, continuous bucket conveyor systems are essential material handling tools that offer many advantages for various industries. With proper design, maintenance, and safety measures, these systems can help improve efficiency, reduce labor costs, and ensure safe and reliable operation.