The Evolution and Advantages of Rubber Chains in Bucket Conveyors

In the realm of conveyor systems, the rubber chain for bucket conveyors stands out as a pivotal innovation, revolutionizing material handling processes across industries. These chains play a critical role in ensuring efficient and seamless transportation of bulk materials, offering a myriad of benefits such as non-fall bucket assurance, gap-free operation, and simplified maintenance procedures.

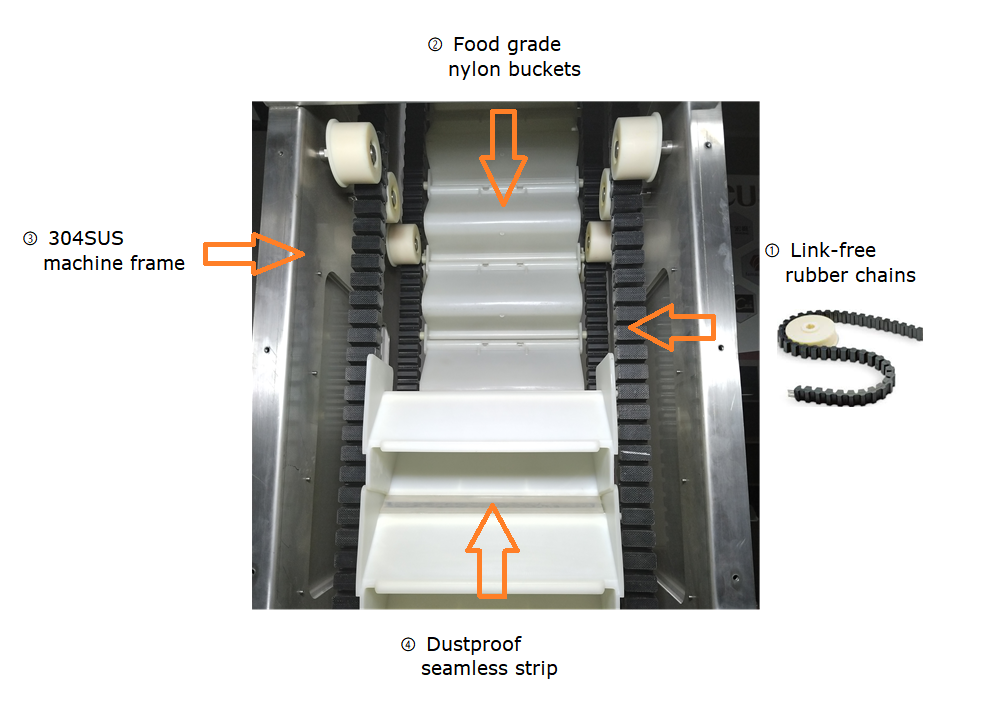

Importance of Rubber Chains in Bucket Conveyors

1. Non-fall Bucket Assurance

The primary concern in any conveyor system is the secure transport of materials without spillage. Rubber chains for bucket conveyors are engineered with meticulous precision to ensure that buckets securely hold and transport materials without any spillage or accidental discharge. This attribute is particularly crucial in industries dealing with fragile or high-value materials where loss or damage due to spillage is not an option.

According to a study by Global Market Insights, the demand for spillage-free conveyor systems is expected to witness significant growth in the coming years, with a strong emphasis on non-fall assurance mechanisms. Rubber chains have emerged as a reliable solution to address this critical requirement, thereby gaining widespread adoption in various industries like agriculture, mining, food processing, and more.

2. Gap-Free Operation

Another key advantage of rubber chains for bucket conveyors lies in their ability to function without gaps. Traditional chain conveyors often face issues related to material spillage and jamming due to gaps between chains or between the chains and the conveyor bed. Rubber chains, with their seamless and gap-free design, eliminate such problems, ensuring a smooth and continuous material flow throughout the conveyor system.

A report by Grand View Research indicates that the demand for conveyor systems offering uninterrupted and seamless material flow is on the rise, especially in industries where operational efficiency is paramount. Rubber chains contribute significantly to achieving this goal by enabling uninterrupted material transportation without the risk of spillage or blockages.

3. Easy Maintenance

Maintenance is a critical aspect of any conveyor system to ensure optimal performance and longevity. Rubber chains for bucket conveyors are designed with a focus on minimizing maintenance requirements. Their durable and wear-resistant nature reduces the frequency of replacements, resulting in lower downtime and overall maintenance costs.

Studies by Technavio suggest that industries are increasingly investing in conveyor systems that require minimal maintenance and offer extended operational life. Rubber chains fulfill this requirement by providing longevity and reliability, thereby contributing to cost savings and enhanced operational efficiency for businesses.

Benefits of Rubber Chains in Bucket Conveyors

a. Enhanced Material Safety

Rubber chains ensure the safe and secure transportation of materials without the risk of spillage or contamination, preserving the integrity of the conveyed goods.

b. Improved Operational Efficiency

The non-fall assurance and gap-free operation of rubber chains result in smoother material flow, reducing downtime and enhancing overall operational efficiency.

c. Cost-effectiveness

With their durable construction and reduced maintenance requirements, rubber chains offer a cost-effective solution by minimizing replacement costs and maintenance expenses.

d. Environmental Sustainability

Rubber chains made from eco-friendly materials contribute to sustainability efforts by reducing environmental impact and promoting recyclability.

In conclusion, rubber chains for bucket conveyors have become an indispensable component in modern material handling systems. Their ability to ensure non-fall bucket assurance, operate without gaps, and offer easy maintenance aligns perfectly with the evolving needs of industries striving for efficiency, safety, and sustainability in their operations.

As technology continues to advance, the evolution of rubber chains is expected to further enhance their capabilities, making them even more integral to the smooth functioning of conveyor systems across diverse industrial sectors.