Spiral Conveyor Systems: Leading Packaging Solutions

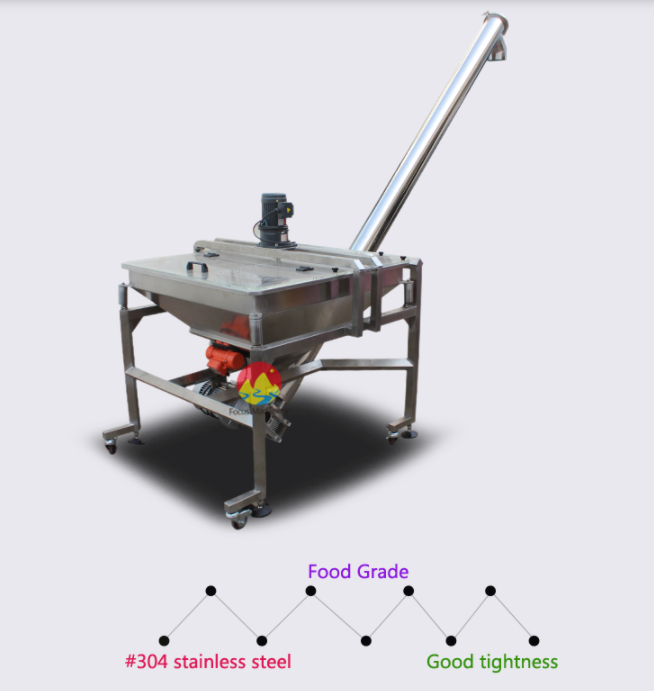

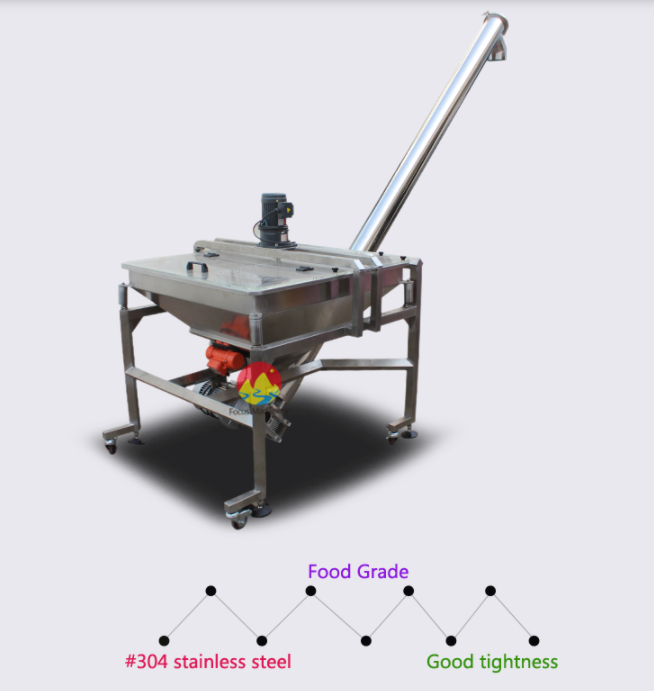

The spiral conveyor systems are safe and reliable transport and has the function of continuous down moving. Spiral Conveyor is a kind of conveying equipment widely used in chemical, building materials, grain, and other departments. For elevation change with a minimal footprint, the spiral conveyor belt is ideal. It is mainly used to transport powdery, granular, and small block materials. In this article, we will walk through what spiral conveyor really shines and their applications.

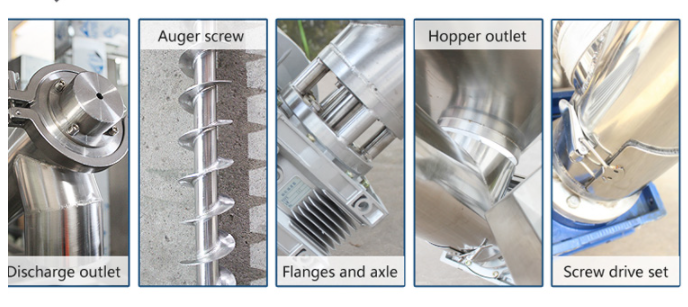

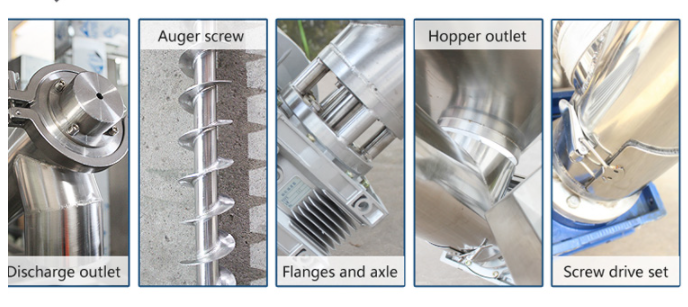

The design of the separation between the hopper and auger screw makes the installation and disassembly easier. Many spirals are shipped as one piece, pre-assembled, and tested.

● Flexible spiral conveyor is used in a wide range of applications, including handling packages or shipments in logistical processes, primary and secondary packaging of consumer items, and print processing.

● Gravity spiral conveyor are suitable for all types of products and industries. Increase efficiency by balancing speed differentials on the production line, delaying product processing, or buffering items in intermittent processes offline.

● Spiral belt conveyor can transfer items from A to B with minimal transfers. Our transmission technology is low investment due to simple, long lasting operation and integrated curves and slopes.

As we mentioned above, the Spiral conveyor is a compact and versatile elevating solution. Spiral can be designed to carry product between floors and machines or over aisles. When it comes to customized spiral conveying solutions, Focusconveyor is one of the professional spiral conveyor manufacturers in China, contact us today!

Advantages of spiral screw conveyor:

● Easy to clean

Unique dust-proof design, keep the products clean and hygienic. The auger screw has a forward and reverses function, which is easy to clean materials inside the auger screw.● Capacity

Compared to other conveyors, the greatest benefit of spiral conveyors is capacity. It can convey the products continuously and you can fill the spiral with products.● Save space

With a small operating footprint and the vertical elevation, spirals take up a fraction of the floor space of a traditional conveyor, resulting in potentially significant financial savings, as well.● Single drive

Typically, only one drive is required for spiral conveying. This means cost savings, noticeable energy savings, and easier controls integration.

● Ease of installation

The design of the separation between the hopper and auger screw makes the installation and disassembly easier. Many spirals are shipped as one piece, pre-assembled, and tested.

Applications of spiral conveyor:

● Flexible spiral conveyor is used in a wide range of applications, including handling packages or shipments in logistical processes, primary and secondary packaging of consumer items, and print processing.

● Gravity spiral conveyor are suitable for all types of products and industries. Increase efficiency by balancing speed differentials on the production line, delaying product processing, or buffering items in intermittent processes offline.

● Spiral belt conveyor can transfer items from A to B with minimal transfers. Our transmission technology is low investment due to simple, long lasting operation and integrated curves and slopes.

Conclusion

As we mentioned above, the Spiral conveyor is a compact and versatile elevating solution. Spiral can be designed to carry product between floors and machines or over aisles. When it comes to customized spiral conveying solutions, Focusconveyor is one of the professional spiral conveyor manufacturers in China, contact us today!