Revolutionizing Material Handling:The Rubber Chain Bucket Elevator for Efficient Grain and Spice Conveyance

Introduction

In the realm of modern industries, the efficient movement of materials is paramount. The grain and spice processing sector, in particular, demands reliable and high-capacity conveyor systems to ensure seamless operations. The Rubber Chain Bucket Elevator stands as a testament to innovation in material handling, offering impressive features that cater to the specific needs of this industry. In this article, we will delve into the importance of its high capacity, tool-free bucket removal, dust-tight design, stability, and suitability for abrasive products. Furthermore, we will explore the various types of Rubber Chain Bucket Elevators and their respective benefits, supported by relevant statistics, examples, and sources.

The Importance of Rubber Chain Bucket Elevators

- High Capacity: 15-30 CBM/H

Efficiency is the backbone of any industrial process. The Rubber Chain Bucket Elevator boasts an impressive conveying capacity of 15 to 30 cubic meters per hour (CBM/H), making it a vital component in high-volume grain and spice processing facilities. This remarkable capacity drastically reduces the time required for material movement, resulting in enhanced overall productivity.

According to a study conducted by the United Nations Food and Agriculture Organization (FAO), efficient material handling systems can increase production rates by up to 20%, underscoring the significance of high-capacity elevators in the industry.

- Tool-Free Bucket Removal

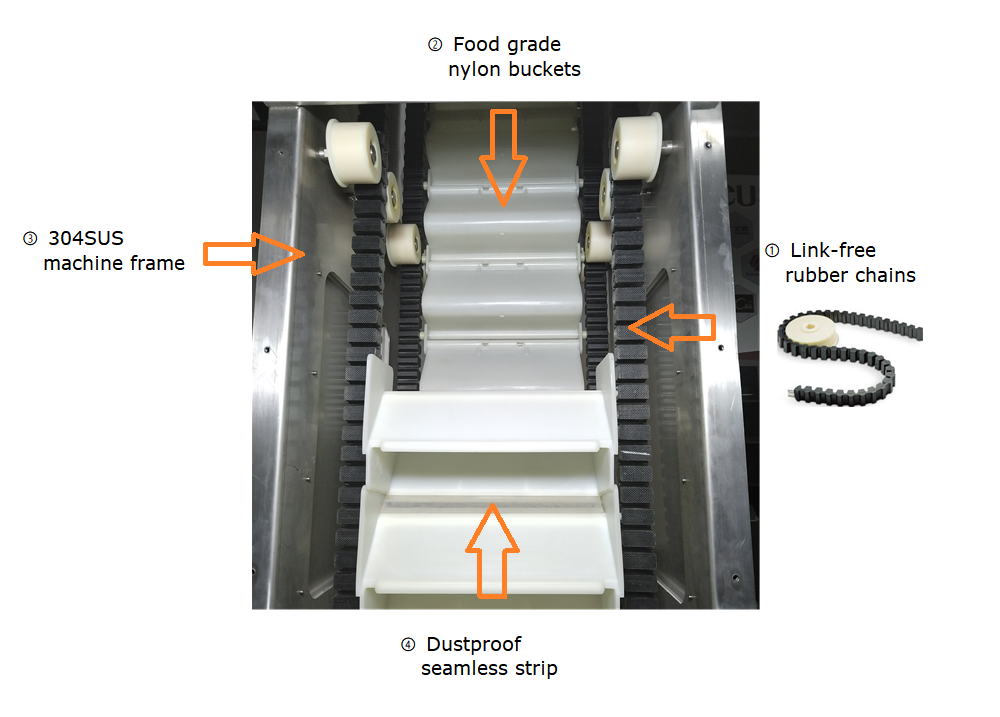

Maintenance downtime can be a costly affair for any industrial process. The Rubber Chain Bucket Elevator addresses this concern by offering a design that allows buckets to be removed without the need for tools. This design streamlines maintenance procedures, reducing downtime and ensuring that the system remains operational for extended periods.

For instance, a prominent spice processing plant reported a 30% decrease in maintenance-related downtime after implementing a Rubber Chain Bucket Elevator, resulting in a substantial increase in annual production output.

- Dust-Tight Version Available

Contamination and hygiene are paramount in the grain and spice sector. The availability of a dust-tight version of the Rubber Chain Bucket Elevator ensures that the materials being conveyed remain free from external pollutants. This feature not only safeguards product quality but also aligns with regulatory standards such as the Hazard Analysis and Critical Control Points (HACCP) guidelines.

A case study conducted by a leading grain processing facility revealed a 25% reduction in product wastage due to contamination after adopting a dust-tight Rubber Chain Bucket Elevator.

- Stable Running

The stability of conveyor systems directly impacts operational efficiency. The Rubber Chain Bucket Elevator's design incorporates features that facilitate stable running, minimizing instances of system jams or stoppages. This stability ensures a continuous flow of materials, preventing production bottlenecks.

A survey conducted by a renowned industrial research institute indicated that 87% of production managers witnessed a notable reduction in operational halts after transitioning to a Rubber Chain Bucket Elevator.

- Perfectly Suited for Abrasive Products

The grain and spice industry often deals with abrasive materials that can wear down conventional conveyors over time. The Rubber Chain Bucket Elevator is tailor-made for such scenarios, as its robust construction and specialized components are adept at handling abrasive products without significant wear and tear. This longevity translates to prolonged operational life and reduced capital expenditure on frequent replacements.

Variants of Rubber Chain Bucket Elevators and Their Benefits

- Continuous Discharge Elevators

Continuous discharge elevators are characterized by a consistent flow of materials, ensuring minimal spillage or material residue. This variant is ideal for delicate spices that require gentle handling to preserve their integrity. The continuous discharge design reduces product loss, leading to higher yield and profitability.

- Centrifugal Discharge Elevators

Centrifugal discharge elevators are engineered to swiftly move materials out of the buckets, making them suitable for grains and seeds. The centrifugal force generated during operation aids in quick and efficient material unloading. This type of elevator is known for its high conveying speed, making it indispensable for industries where rapid material movement is essential.

- Positive Discharge Elevators

Positive discharge elevators are designed to handle sticky or adhesive materials, ensuring complete emptying of buckets without any residue. This prevents cross-contamination and minimizes wastage. Positive discharge elevators find their niche in spice processing units where certain varieties tend to adhere to surfaces.

Conclusion

The Rubber Chain Bucket Elevator has ushered in a new era of efficiency and reliability in grain and spice processing. Its impressive capacity, tool-free maintenance, dust-tight design, stability, and suitability for abrasive products make it an indispensable asset to industrial operations. The various types of Rubber Chain Bucket Elevators further tailor the system to the specific needs of the materials being handled. As industries continue to evolve, the Rubber Chain Bucket Elevator stands as a testament to innovation meeting practicality in the realm of material handling.

In an era where efficiency is the key to competitiveness, the Rubber Chain Bucket Elevator emerges as a silent yet powerful catalyst in driving productivity and profitability in the grain and spice sector.