How to Track a Conveyor Belt

One of the most common industrial conveyor belt problems is that the conveyor belt slips out of alignment and starts to go off-center, and tracking a conveyor belt on the belt conveyor system is a way to optimize the adjustment of the idler, pulleys, and loading conditions. You can accomplish the tracking process with a simple rule, “The belt tracks to the side with the least tension, and moves toward that end of the roll/idler it contact first. ” A full understanding of belt tracking measures and proper use of these measures can correct belt tendency. In this article, we will walk through the basic rules of belt tracking.

Things Need to Be Considered When You Track Bucket Elevator Conveyor Belt:

The bucket conveyor belt is running in an unstable equilibrium state. If it is affected by the slightest external factors, such as off-center loading of product, dirt between belt and pulley, belt distortion or lateral feeding or diverting of goods, it will cause the direction Sideways. Therefore, the following factors need to be considered when tracking the wheel:

1. All pulleys and rollers must be installed at right angles to the belt running shaft.

2. The supporting structure must be stable and rigid to withstand all the forces acting on it, including the weight of the transported items, belt tension, etc.

3. For the belt conveyor parts that will contact the belt, use belt conveyor guarding parts that prevent dirt and clean them regularly.

Belt Conveyor Alignment Procedure:

Belt tracking is divided into basic measures and additional measures. The former will only keep the correctly aligned belt in its center position, while additional measures are needed when the basic measures alone are insufficient or not suitable for adequate control of belt tracking. Here are 3 tracking rules for you to follow to track the conveyor belt:

1. The belt tracks to the side with the least tension.

● Equipped with multiple cylindrical conical or radial crown pulleys to ensure straight and stable operation.

● In installations with a clear tendency to loss and considerable lateral forces ( diverter bar, side feed, a large amount of redirection in the belt path, etc.), additional belt tracking measures are required.

2. The greater the arc of contact, the greater the friction and the greater the tracking effect.

● To keep the belt tension as low as possible, the pivoting movement should be as perpendicular as possible to the center line of the contact arc (plane A ↔ B). The center distance between the end pulley and the guide pulley should be at least twice the diameter of the larger pulley.

3. For the conveyor bend pulley and belt conveyor rollers, the belt that first contacts will have a greater tracking effect.

● To achieve the maximized tracking effect, the inclined rollers should be installed in the running-on side in front of the tail pulley.

● Due to the high friction coefficient, positioning the roller on the conveying side of the belt can produce a good tracking effect.

● Belt tracking is further improved when the inclined rollers are angled forward by 8° to 10° at the belt edges in the running direction of the belt.

● The belt contact of a roller should be around ¼ of the belt width and the rollers angle of incline should be 5° to 10°.

According to the rules that we mentioned above, we can track a conveyor belt in easy steps. If you need to move the conveyor belt to the left, tap the bolt on the left to make the snub roller move. After adjusting the position of the snub roller, tighten the bolt to keep the snub roller at the newly adjusted position. Repeat these steps until the center of the conveyor belt is within a quarter of an inch of the center of the tail pulley.

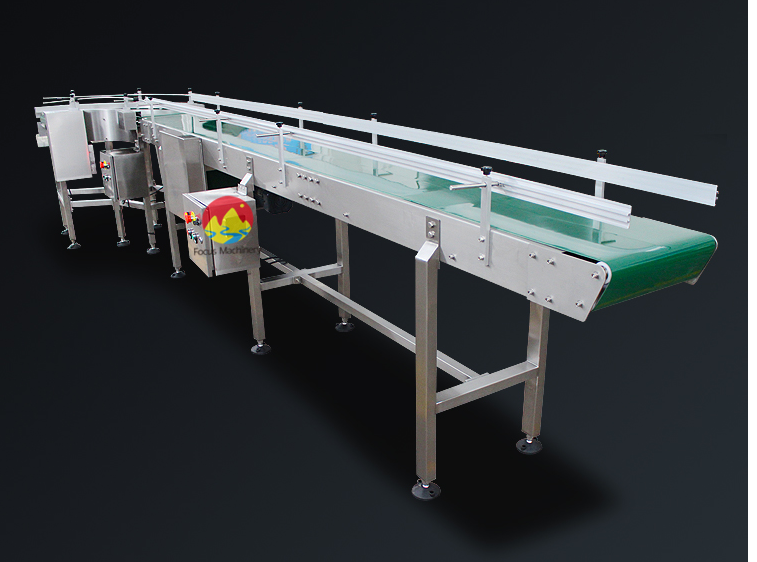

Food grade conveyor belt specification:

| Model | 90 degree turning belt conveyor 90 degree belt conveyors |

| Machine Frame | 304 stainless steel or carbon steel |

| Belt Material | PP belt, PVC belt, PU belt, Stainless steel belt |

| Machine Height | To be customized |

| Voltage | AC220v or three phase 380v, 50hz/60hz |

| Power Supply | 1.1kw |

Conclusion

Samsonpac is one of the professional food grade belt conveyor manufacturers and conveyor parts suppliers in China. If you would like to know more about our conveyors, or our consultancy, design and product development services, please call us on+86 13925923303, or send an email to admin@focuspack.net.