How to Choose the Right Conveyor Belt

When you are choosing an Inclined Belt Conveyor, cleated belt conveyor, and other conveyors, have you noticed their belt? In other words, have you taken the belt into your consideration, when you are purchasing the belt conveyor from the belt conveyor systems manufacturers?

A conveyor belt is one of the important parts of the conveying system. As the major operator of the conveying, the quality of the conveyor belt also affects the efficiency of the conveying.

A conveyor belt is one of the important parts of the conveying system. As the major operator of the conveying, the quality of the conveyor belt also affects the efficiency of the conveying.

If the conveyor belt is not suitable for conveying your products, the conveyor system would not normally work. To make your belt conveyor works without effort, it is necessary to select the right belt. Today, I will list the most important factors that you need to consider when you are selecting the conveyor belt.

Factors to Consider While Selecting a Conveyor Belt

There are four elements you need to consider when you are purchasing the belt conveyor. If you take them into the consideration about the conveyor belt, you can take a step nearer to buying the right belt conveyor.

Product Size

The length, width, and height of products are the first and the most important factor in your decision. Before you purchase the belt conveyor, you should get a full understanding of the overall size of the conveyed products. If the height and width of the belt are not bigger than the overall size of the products, the conveyed products would get stuck during the conveying process.

Product Weight

The weight of the product would directly affect the working of the belt. Different materials of the belts offer different bearing capacities. If the weight of the product is over the bearing capacity of the belt, the belt would get bent or wrapped. Therefore, weight is the second factor you need to consider.

Types of the Belt

Each type of belt has advantages in conveying. The type of belt you choose depends on what product you determine transport. Take an instance, if you are planning to use the belt conveyor to transport the metal product, you should choose the belt that could withstand the sharp edges of the products.

Operating Environment

Generally speaking, the conveyors that can operate in an indoor environment at room temperature are more flexible in belt options. But some special environment or extreme environment conditions require specific belting, such as stainless steel wire mesh belting for high heat environments.

Type of Belt

As above mentioned, each type of belt could be used to convey specific products, with their specific advantages. In the following parts, I will introduce you to three major types of belts and what they can convey.

Flat Belt

The flat belt is consists of continuous single loops. The flat belt is commonly seen in many conveyor systems. It is because the flat belt conveyor is the universal system for most transporting sections, which can be used to transport items within a facility. The belt is made either of natural material or synthetic fabric(ex. polyester, nylon).

Application: The flat belt system is the first choice for industrial environments, slow assembly lines, and wash-down areas. Also, it could convey those irregular, soft, or small items without damaging them.

Application: The flat belt system is the first choice for industrial environments, slow assembly lines, and wash-down areas. Also, it could convey those irregular, soft, or small items without damaging them.

Modular Belt

Unlike the flat belt, the modular belt system adopts a single loop made of countless interlocked pieces, usually made of hard plastic. Because of its structure, the segments can be removed and replaced individually, instead of abandoning the entire belt.

Furthermore, it is easier to clean, as well as more resistant to sharp and abrasive materials. That means the modular belt is more durable and lower-maintenance than the flat belt. In addition, the plastic modular belt allows the specific design of the machine without affecting the belt tracking.

Application: Because it is easy to clean, it can be used to transport food. Because of the adjustable structure, the modular belt conveyor is suitable for applications where fluid should be either drained or retained as it is carried on the conveyor.

Furthermore, it is easier to clean, as well as more resistant to sharp and abrasive materials. That means the modular belt is more durable and lower-maintenance than the flat belt. In addition, the plastic modular belt allows the specific design of the machine without affecting the belt tracking.

Application: Because it is easy to clean, it can be used to transport food. Because of the adjustable structure, the modular belt conveyor is suitable for applications where fluid should be either drained or retained as it is carried on the conveyor.

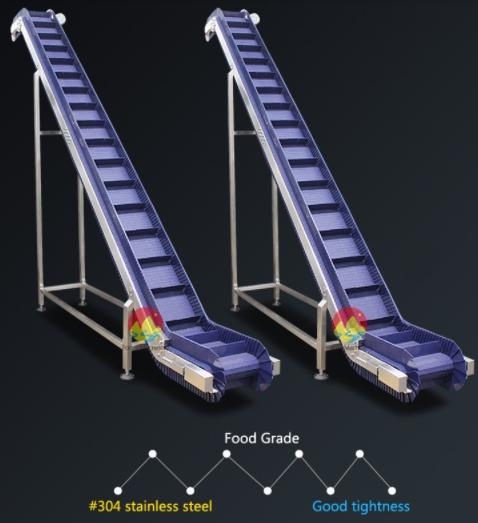

Cleated Belt

The cleated belt is designed with vertical cleats or barriers. The cleats could ensure the conveyed products are stable and the certain distance between them during the inclines and declines. The cleats come in different shapes, each with its own application.

●Inverted Capital “T” This cleat stands perpendicular to the belt face, offering support and flexibility in handling delicate items. It is suitable for light-duty works, such as food, nut, small components.

●Forward-Leaning Capital “L”. The wide base of this cleat makes the cleated belt conveyor more resistant to leverage forces. Therefore, this type of cleated belt conveyor can be used to carry light- to medium-weight bulk products up steeper inclines.

●Inverted “V”. This type of cleat is usually 2 inches or less in the height, to achieve the troughing effect. It is perfect for transporting abrasive, heavy, or large-piece bulk products because it could withstand such a weight.

●Lugs & Pegs. These two types of cleats can meet specific transporting needs. For example, it could help to run-off liquids when used to transport the washed vegetables.

Conclusion

Choosing the right belt is the most important aspect when you are purchasing the belt conveyors. It is because the belt could determine how your machine transports your items and the future maintaining issue. Focus Conveyor, a China professional belt conveyor manufacturers, sells a variety of belt conveyors which could meet your diverse needs.