Enhancing Efficiency and Safety with Non-Fall Bucket Elevators

Introduction

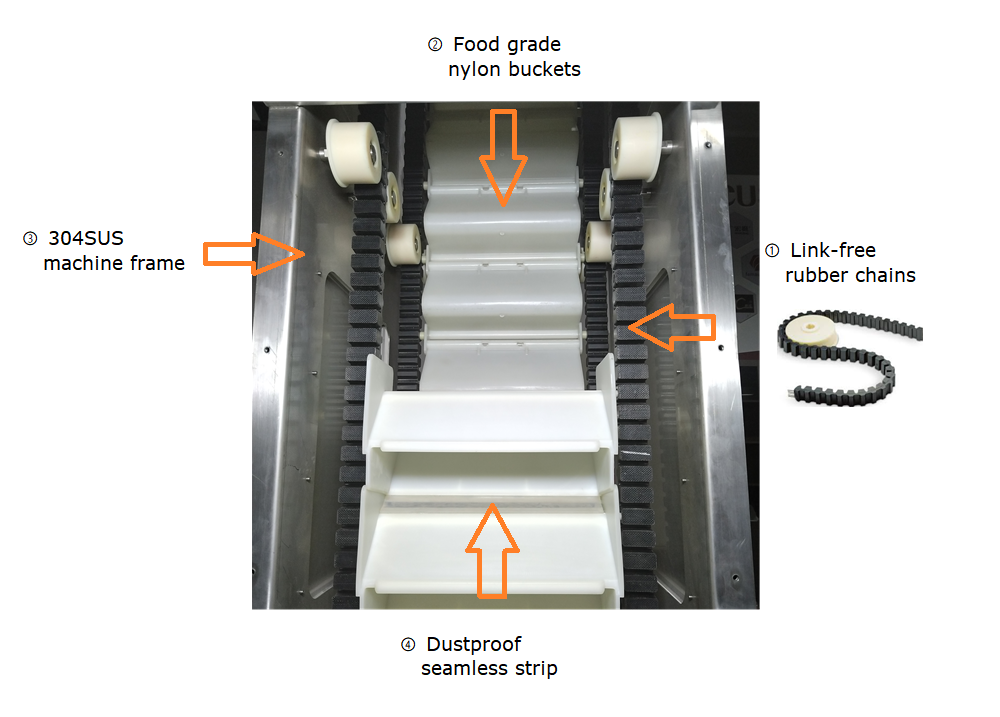

Bucket elevators are crucial components in various industries, used to efficiently transport bulk materials and products vertically. Traditionally, they have been associated with certain challenges, including product spillage and safety concerns. However, with advancements in technology and materials, non-fall bucket elevators have emerged as a solution to these issues. In this article, we will explore the key features and benefits of non-fall bucket elevators, with a focus on link-free rubber chains, food-grade nylon buckets, 304 stainless steel machine frames, and dustproof seamless strips.

The Need for Non-Fall Bucket Elevators

Traditional bucket elevators, while effective at moving materials vertically, have often been plagued by issues such as product spillage and maintenance challenges. These issues can result in lost productivity, increased safety risks, and potential contamination of the transported materials. As a result, the demand for more efficient and reliable bucket elevators led to the development of non-fall bucket elevators, which address these concerns effectively.

Key Features of Non-Fall Bucket Elevators

- Link-Free Rubber Chains

Link-free rubber chains are a pivotal component of non-fall bucket elevators. They replace traditional steel or metal chains, offering numerous advantages. The most significant advantage is the elimination of product spillage. Rubber chains create a smooth and continuous surface, preventing materials from getting trapped in the gaps between links.

-

Reduced Maintenance: Link-free rubber chains are more durable and require less maintenance compared to traditional chains. They are resistant to corrosion and have a longer lifespan, reducing downtime for maintenance.

-

Enhanced Safety: The absence of sharp metal edges on link-free rubber chains reduces the risk of injuries during maintenance and operation.

-

Increased Efficiency: The smooth surface of rubber chains minimizes friction, allowing for smoother material flow and reducing energy consumption.

-

Noise Reduction: Rubber chains produce less noise during operation, contributing to a quieter and more comfortable working environment.

- Food-Grade Nylon Buckets

Food safety is paramount in industries where materials being transported are meant for human consumption. Non-fall bucket elevators equipped with food-grade nylon buckets ensure the safe handling of edible products, adhering to strict hygiene standards.

-

Preventing Contamination: Food-grade nylon is non-toxic and resistant to corrosion, ensuring that no harmful substances leach into the transported materials.

-

Easy to Clean: Nylon buckets are easy to clean and sanitize, minimizing the risk of cross-contamination between batches.

-

Reduced Wear and Tear: Nylon is a durable material that withstands the abrasive nature of many food products, ensuring a longer bucket lifespan.

-

Customization Options: Non-fall bucket elevators can be tailored to meet specific food industry requirements, including different bucket sizes and configurations.

- 304 Stainless Steel Machine Frame

The machine frame is the backbone of a bucket elevator, providing structural support and ensuring the integrity of the system. Non-fall bucket elevators often feature machine frames made from 304 stainless steel, a material known for its strength and resistance to corrosion.

-

Corrosion Resistance: 304 stainless steel is highly resistant to corrosion and rust, even in harsh industrial environments. This extends the equipment's lifespan and reduces maintenance costs.

-

High Strength: The strength of stainless steel ensures that the machine frame can support heavy loads and withstand the stresses of operation without deformation.

-

Hygienic: Stainless steel is easy to clean and maintain, making it ideal for industries where hygiene is a top priority.

-

Aesthetically Pleasing: The smooth, polished appearance of stainless steel adds a professional and clean look to the equipment, which is important in food and pharmaceutical industries.

- Dustproof Seamless Strip

Dust and material spillage can be a significant problem in bucket elevators, not only causing environmental concerns but also safety risks and increased maintenance. Non-fall bucket elevators often come with dustproof seamless strips, which effectively contain and prevent material leakage.

-

Improved Safety: By containing dust and spillage, the risk of slips and falls is significantly reduced, making the workplace safer for operators.

-

Environmental Compliance: Dust containment helps companies meet environmental regulations by reducing the release of materials into the environment.

-

Reduced Cleanup and Maintenance: Dustproof strips minimize the need for frequent cleaning and maintenance, saving both time and money.

-

Enhanced Efficiency: By preventing material loss, more of the transported product reaches its intended destination, maximizing efficiency and reducing waste.

Case Studies and Success Stories

Non-fall bucket elevators have been adopted in various industries with impressive results. Let's look at a couple of case studies to highlight their benefits:

-

Grain Handling Facility:

A grain handling facility in the Midwest of the United States upgraded its traditional bucket elevators to non-fall bucket elevators equipped with link-free rubber chains and food-grade nylon buckets. The facility reported a 15% reduction in product loss due to spillage, resulting in annual savings of over $50,000. The decreased maintenance and increased operational efficiency further boosted their profitability.

-

Pharmaceutical Manufacturing Plant:

A pharmaceutical manufacturing plant in Europe integrated non-fall bucket elevators with 304 stainless steel frames and dustproof seamless strips into its production process. This not only ensured the safe handling of sensitive pharmaceutical materials but also improved cleanliness and reduced the risk of cross-contamination. The plant saw a 30% reduction in downtime for cleaning and maintenance, resulting in an estimated annual savings of €100,000.

Conclusion

Non-fall bucket elevators, equipped with link-free rubber chains, food-grade nylon buckets, 304 stainless steel machine frames, and dustproof seamless strips, represent a significant advancement in bulk material handling technology. They offer numerous benefits, including enhanced safety, reduced maintenance, improved efficiency, and compliance with industry-specific requirements. The case studies provided demonstrate how these advancements can lead to substantial cost savings and increased profitability for companies across various sectors. As industries continue to prioritize safety, efficiency, and product integrity, non-fall bucket elevators have become a compelling solution for addressing the challenges associated with traditional bucket elevators.