Enhancing Efficiency and Hygiene in Food Industries with Waterproof Belt Conveyors

Introduction

In the ever-evolving landscape of the food industry, innovation is key to maintaining high standards of efficiency, cleanliness, and safety. One of the breakthroughs in this regard is the adoption of Waterproof Belt Conveyors. These ingenious systems have become widely popular for their versatile applications in food processing and packaging. In this article, we will explore the waterproof belt conveyor in depth, focusing on its significance in food industries, its easy-to-install and remove structure, and the numerous advantages and benefits it offers, particularly its ease of cleaning and washability.

Waterproof belt conveyors have gained immense popularity in food industries, owing to their suitability for a variety of tasks. According to industry reports, the global food conveyor systems market is expected to grow steadily, reaching a value of $4.5 billion by 2025. This growth is driven by the increasing demand for processed foods and the need for more efficient conveyor systems in the industry.

These conveyors play a vital role in the production and packaging of a wide range of food products, including but not limited to:

1. Meat and Poultry: Waterproof belt conveyors are used to transport raw meat, poultry, and fish in processing plants. These conveyors help maintain a hygienic environment and reduce the risk of cross-contamination.

2. Bakery Products: In bakeries, these conveyors are used to transport dough, baked goods, and even toppings and fillings, ensuring a smooth and efficient production process.

3. Fruits and Vegetables: Conveyor systems are crucial for sorting, washing, and packaging fruits and vegetables. Waterproof belts ensure the products remain uncontaminated during the process.

4. Dairy Products: Milk and dairy processing facilities benefit from waterproof belt conveyors, which enable the seamless movement of products like cheese, yogurt, and milk cartons.

5. Beverage Industry: Bottling and canning plants utilize waterproof belt conveyors to transport beverages while maintaining cleanliness and hygiene.

One of the standout features of waterproof belt conveyors is their user-friendly installation and removal process. These systems are designed for convenience and efficiency, making them a preferred choice in the food industry.

1. Modular Design: Waterproof belt conveyors are typically constructed with a modular design, allowing for easy assembly and disassembly. This means that they can be quickly reconfigured to adapt to changing production needs.

2. Tool-Free Installation: Many waterproof belt conveyors come with tool-free installation options, eliminating the need for specialized equipment or skilled labor during setup. This reduces installation time and associated costs.

3. Minimal Downtime: The ease of installation and removal means that maintenance or repairs can be conducted swiftly, minimizing production downtime. In a fast-paced industry like food processing, minimizing downtime is crucial to meet production targets.

4. Scalability: Food manufacturers appreciate the scalability of waterproof belt conveyors, as they can easily expand their production lines without major disruptions. This adaptability is particularly beneficial in a market where consumer demands can change rapidly.

Waterproof belt conveyors offer a multitude of advantages and benefits that significantly enhance their value in the food industry. Let's delve into some of the key advantages:

1. Easy to Clean

Maintaining cleanliness and hygiene is paramount in food processing. Waterproof belt conveyors are specifically designed to meet these requirements. They can be cleaned quickly and efficiently, reducing the risk of bacterial contamination. Here are some ways they facilitate easy cleaning:

1.1. Material Choice: Many waterproof belt conveyors are made from food-grade materials like stainless steel or plastic, which are resistant to corrosion and easy to clean.

1.2. Open Design: Some conveyors feature an open structure that allows easy access for cleaning. Debris and residue can be removed swiftly to prevent buildup.

1.3. Sanitary Belts: These conveyors often use belts with a sanitary design that minimizes crevices and areas where food particles can accumulate.

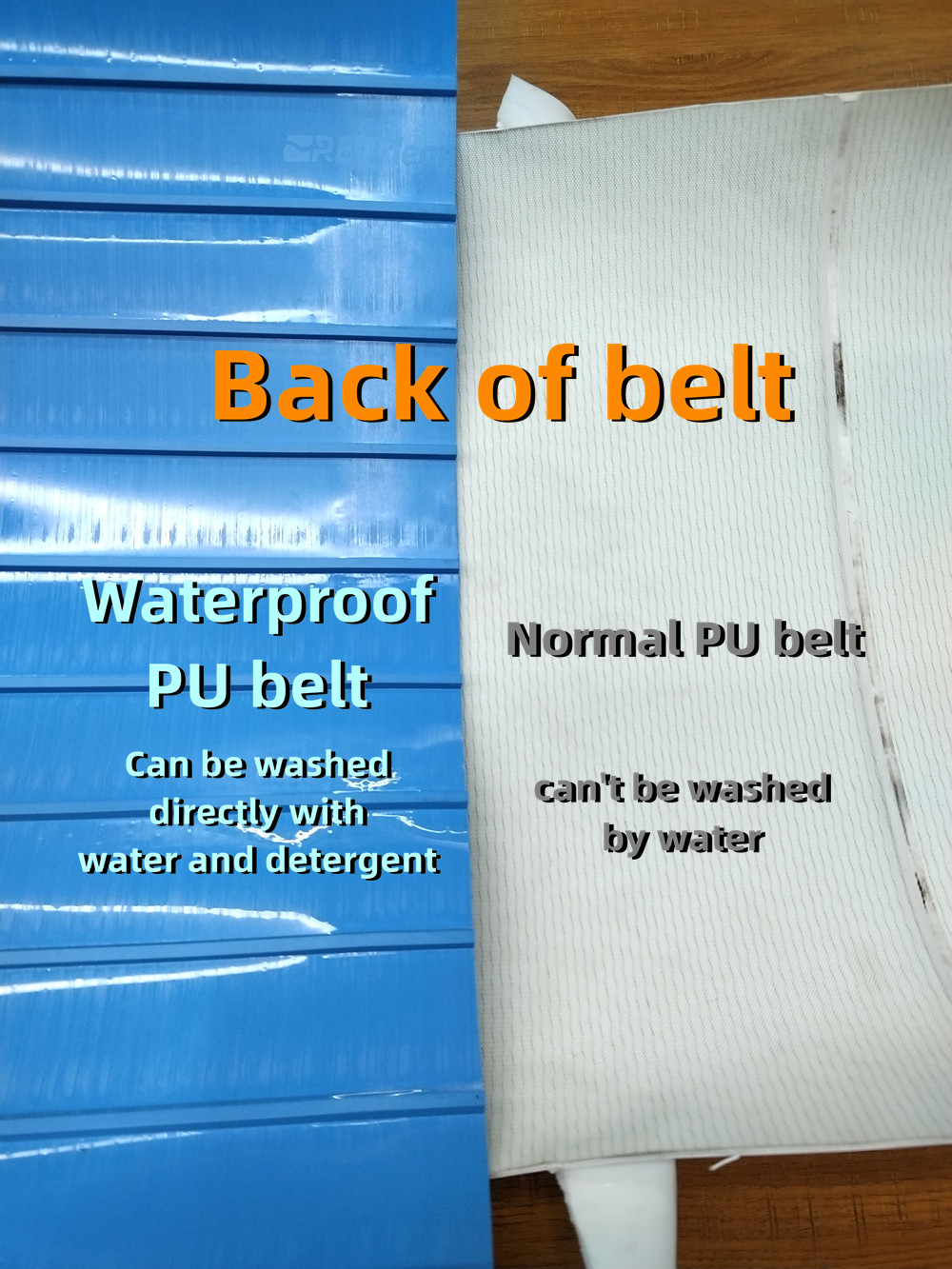

2. Washable with Water and Detergent

Waterproof belt conveyors live up to their name by being truly waterproof. They can be washed directly with water and detergent, simplifying the cleaning process further. This is especially important in industries where stringent hygiene standards are imposed.

2.1. High-Pressure Cleaning: Some models can withstand high-pressure washing, ensuring that all contaminants are effectively removed.

2.2. Chemical Resistance: Waterproof belts are often resistant to common cleaning chemicals, making it safe to use detergents without damaging the conveyor.

2.3. Easy Drainage: These conveyors are designed with drainage systems that prevent water from pooling, ensuring thorough cleaning and quick drying.

3. Hygiene Compliance

Waterproof belt conveyors contribute to compliance with food safety regulations and standards such as Hazard Analysis and Critical Control Points (HACCP) and Good Manufacturing Practices (GMP). Meeting these requirements is essential for food manufacturers to build and maintain a positive reputation and avoid costly recalls.

4. Reduced Product Contamination

The seamless and easy-to-clean surface of waterproof belt conveyors minimizes the risk of product contamination. This is especially crucial when handling sensitive food products that must meet strict quality and safety standards.

5. Longevity and Durability

Investing in waterproof belt conveyors pays off in the long run due to their durability. They are resistant to wear and tear, corrosion, and harsh cleaning processes, ensuring a longer service life compared to traditional conveyors.

6. Versatility

These conveyors are versatile and can be adapted for a wide range of applications within the food industry. They can handle different product sizes and weights, making them suitable for various production processes.

7. Cost Efficiency

While the initial investment in waterproof belt conveyors may be higher than traditional conveyors, the long-term cost efficiency and reduced maintenance expenses make them a wise choice for food manufacturers looking to optimize their operations.

Conclusion

Waterproof belt conveyors have emerged as indispensable tools in the food industry, offering a wide range of advantages and benefits. Their easy installation and removal, ease of cleaning, and washability with water and detergent make them stand out as a top choice for food processing and packaging.

As the global food industry continues to grow, embracing innovations like waterproof belt conveyors becomes imperative. Not only do they enhance efficiency and productivity, but they also contribute to maintaining the highest standards of hygiene and product quality. Food manufacturers that invest in these systems are poised to stay competitive in a rapidly evolving market while safeguarding consumer health and satisfaction.