Enhancing Beverage Production Efficiency: The Role of Conveyor Systems

Different Conveyor Systems In Beverage Industry

In the fast-paced beverage industry, efficiency and precision in production processes are paramount. A pivotal component ensuring smooth operations within beverage manufacturing is the Conveyor System. This intricate network of machinery facilitates the seamless flow of bottles, cans, and liquids throughout the production line, significantly enhancing productivity. Within this system, various elements play distinct roles, such as liquid pumps, bottle/can belt conveyors, unscramblers, and other conveyors. Let's delve into the significance, types, and benefits of these components in the beverage industry.

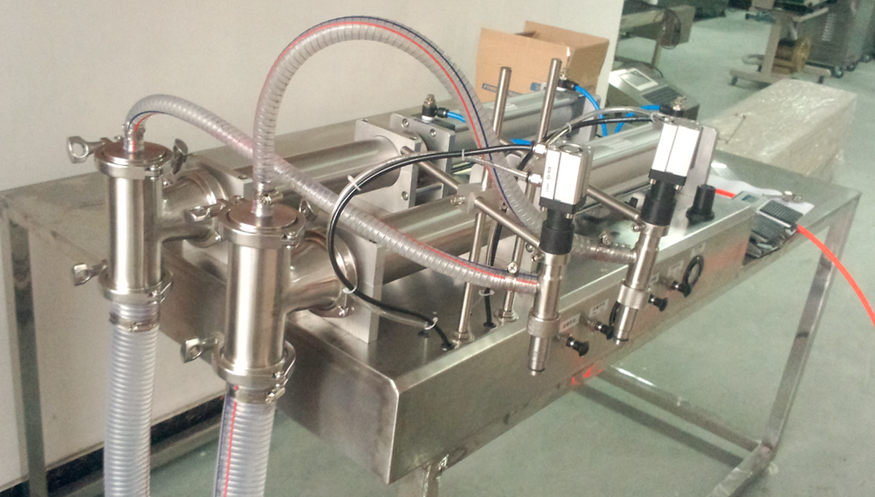

1. Liquid Pump: Streamlining Liquid Flow

Liquid pumps are the workhorses of the beverage industry, ensuring the consistent flow of liquids throughout the production process. These pumps come in various types, including centrifugal, positive displacement, and air-operated diaphragm pumps. Centrifugal pumps, for instance, excel in handling thin liquids like water, while positive displacement pumps are ideal for viscous fluids like syrups or juices.

Importance:

- Maintains a steady flow rate of liquids, reducing wastage and ensuring consistent product quality.

- Enables precision and control in transferring fluids from one stage of production to another, avoiding spillage and contamination.

- Facilitates the efficient mixing of ingredients, ensuring uniformity in the final beverage product.

Benefits:

- Improved productivity due to continuous and controlled liquid flow.

- Minimized product loss, contributing to cost-effectiveness.

- Enhanced product quality and consistency, meeting consumer expectations.

2. Bottles/Cans Belt Conveyor: Efficient Transportation

Bottle/can belt conveyors form the backbone of the production line, efficiently transporting containers from one stage to another. These conveyors come in various configurations, including straight, curved, inclined, or declined belts, tailored to meet specific production requirements.

Importance:

- Facilitates the smooth movement of bottles and cans, reducing the chances of breakage or damage during transportation.

- Allows for easy integration into the production line, enabling a continuous flow of containers between different processing stages.

- Increases operational efficiency by automating the transportation process, reducing manual handling and labor costs.

Benefits:

- Enhanced throughput and production speed due to the consistent movement of containers.

- Reduced risk of product damage, ensuring the integrity of the final beverage product.

- Optimized workflow, leading to overall cost savings and increased profitability.

3. Bottles/Cans Unscrambler: Organizing Container Input

Bottles/cans unscramblers are specialized machines that arrange randomly oriented containers into a single file, ensuring an organized and uniform flow of containers along the production line.

Importance:

- Improves efficiency by aligning containers for seamless integration into the production process, reducing downtime caused by irregular container flow.

- Enhances safety by preventing jams or blockages in the conveyor system, minimizing the risk of accidents and production halts.

- Enables high-speed operations, optimizing the overall production output.

Benefits:

- Increased production line efficiency, reducing bottlenecks and interruptions.

- Improved worker safety by minimizing potential hazards associated with irregular container flow.

- Consistent and reliable container handling, ensuring a smooth workflow.

4. Other Conveyors in the Beverage Industry: Diverse Applications

Beyond the aforementioned components, various other conveyors play crucial roles in beverage production. These include accumulation conveyors, case conveyors, spiral conveyors, and more, each serving distinct functions within the production line.

Importance:

- Accumulation conveyors temporarily store containers, regulating their flow into downstream processes, preventing congestion, and ensuring a continuous production cycle.

- Case conveyors handle packaged products, transporting them for labeling, palletizing, or shipping, streamlining the packaging process.

- Spiral conveyors efficiently move products vertically or in confined spaces, optimizing floor space and enhancing production line layout flexibility.

Benefits:

- Improved production line flexibility and adaptability to diverse manufacturing needs.

- Optimized space utilization, especially in compact production facilities.

- Enhanced product handling and distribution, contributing to efficient packaging and logistics.

Conclusion: Elevating Beverage Production Efficiency

In the ever-evolving landscape of the beverage industry, conveyor systems, equipped with liquid pumps, belt conveyors, unscramblers, and diverse conveyors, stand as indispensable assets. These systems streamline operations, ensure consistency, and enhance productivity, all contributing to the delivery of high-quality beverages to consumers worldwide.

By investing in advanced conveyor technologies and optimizing their integration into the production line, beverage manufacturers can elevate their efficiency, reduce operational costs, and maintain a competitive edge in the market. As the industry continues to evolve, leveraging these conveyor systems' capabilities will remain pivotal in meeting the increasing demands for diverse and superior beverage products.