All You Need To Know About Conveyor System I

What Is A Conveyor?

A conveyor can be used to transport material between various points. Most conveyors consist of three basic elements-frame or belt support, drive and idler. The conveyors are widely used in commercial, industrial, and mining sectors.

What Are Types Of Conveyors?

Conveyors can be divided into two categories-gravity conveyors or power conveyors. There are many types of conveyors, and they include but are not limited to:

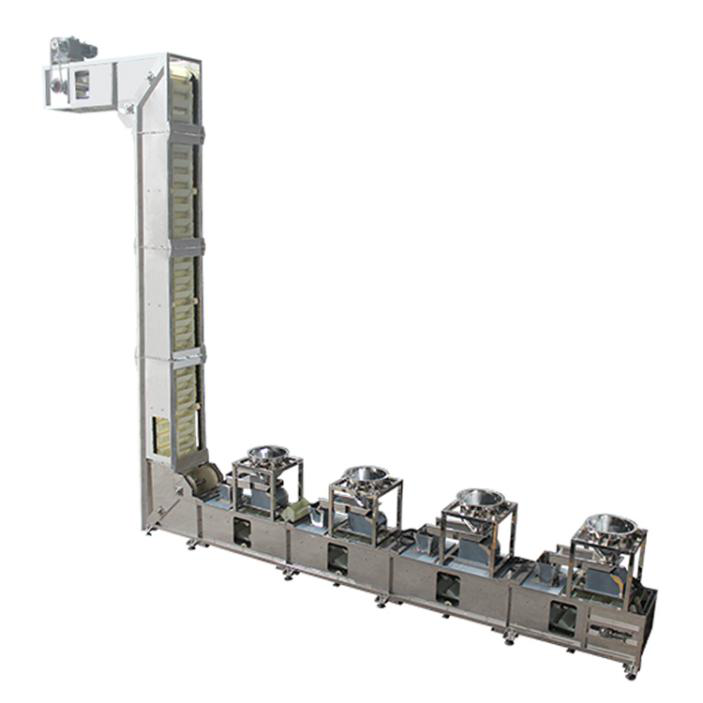

● Single bucket elevator

| Model | FM-3B3 Vertical Lift Conveyor |

| Bucket Volume | Customized(minimum 40L, Maximum 100L) |

| Machine Structure | Stainless steel or carbon steel |

| Production Capacity | Based on the running speed and bucket volume |

| Machine Height | Customized |

| Discharging Height | Customized |

| Hopper Material | 304 stainless steel or carbon steel |

| Voltage | AC220V or three phase 380V, 50hz/60hz |

| Power Supply | 0.75kw |

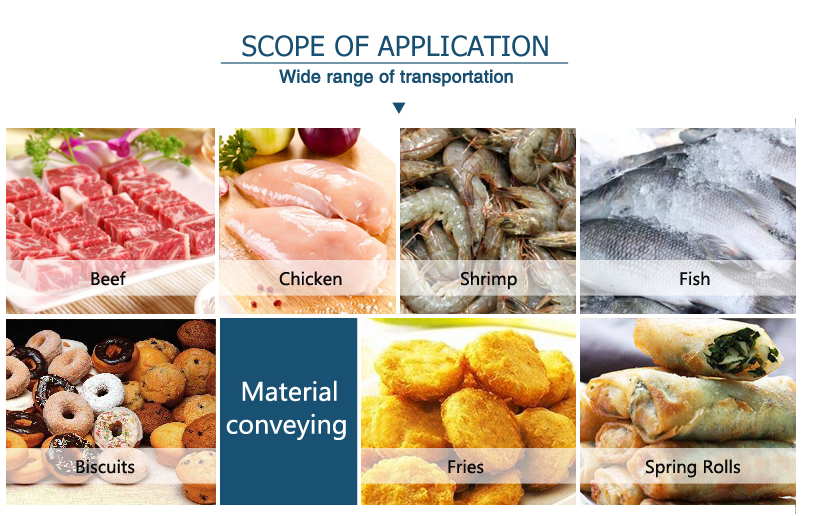

1.The single bucket elevator is used to the packaging system widely.

2.One shot lifting of grain material, such as corn, food, fodder and chemical industry, etc.

3.The electromagnetism oscillator make the food, other material transport stable, evenly and fast.

4.It occupies small room with low running noise, simple operation and easy cleaning.

► Buckets can be installed or released really soon because of the quick release mechanism.

► Automatic chain tension device and built-in overload protection is equipped to guarantee the safety of operation.

► All parts have easy to remove inspection covers and a conveniently located inspection window.

►The buckets are made of food grade reinforced polypropylene, molded in one piece and can handle temperatures from -10 to 60 degrees Fahrenheit.

►The vertical bucket elevator can be interface with different feeding devices because of its multiple feeding location.

1. It can work with other equipment for continuous or intermittent type weighing and packaging line.

2.The bowl, made of 304 stainless steel material, is easy to disassemble and clean.

3.The stainless steel chain and machine frame makes it strong, durable and not easy to deform.

4.It can feed the material twice through flipping the switch and adjusting the timing sequence.

5.Speed is adjustable.

6.Keep the bowl straight without spilling the materials.

7.Can be combined with doypack filling machine, achieving the mixture of granule and liquid packing.

2.One shot lifting of grain material, such as corn, food, fodder and chemical industry, etc.

3.The electromagnetism oscillator make the food, other material transport stable, evenly and fast.

4.It occupies small room with low running noise, simple operation and easy cleaning.

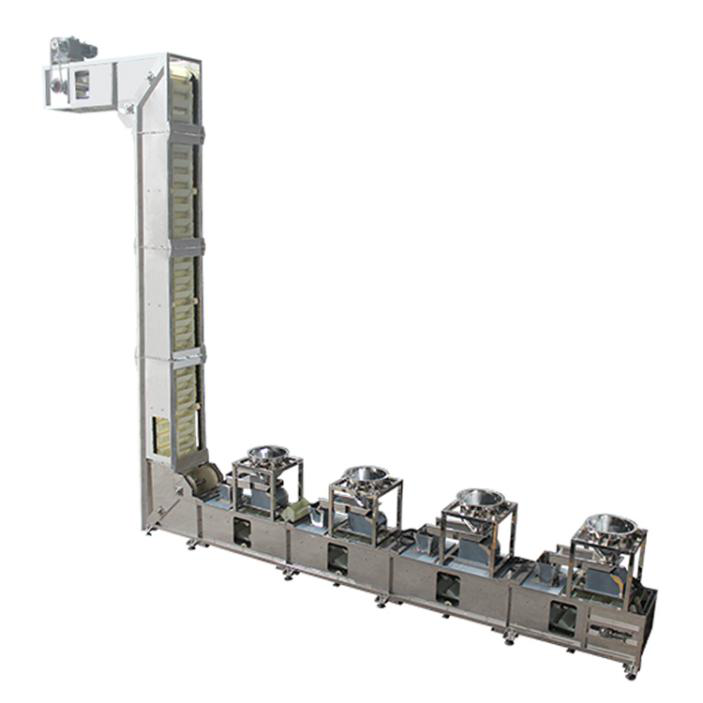

● Continuous bucket elevator

| Model | FM-Z370 Continuous Bucket Conveyor |

| Bucket Volume | 3.7L |

| Machine Structure | Stainless steel or carbon steel |

| Production Capacity | 10-30 m3/h |

| Machine Height | Customized |

| Discharging Height | Customized |

| Hopper Material | Food grade ABS |

| Voltage | AC220V or three phrase 380V, 50hz/60hz |

| Power Supply | 0.75kw |

● Pendulum bucket elevator

| Model | FM-3B3 Bucket conveyor |

| Bucket Volume | 1.0L/1.8L/3.8L/6.5L |

| Machine Structure | Stainless steel or carbon steel |

| Production Capacity | 2-3.5m³/h / 4-6m³/h / 6.5-8m³/h / 8.5-12m³/h |

| Machine Height | 3296mm for standard (1.8L) |

| Discharging Height | 3256mm for standard (1.8L) |

| Hopper Material | Food grade PP, ABS, Stainless steel |

| Packing Size | 2050mmX1350mmX980mmfor standard (1.8L) |

| Voltage | AC220V or three phase 380V, 50hz/60hz |

| Power Supply | 0.75kw |

► Buckets can be installed or released really soon because of the quick release mechanism.

► Automatic chain tension device and built-in overload protection is equipped to guarantee the safety of operation.

► All parts have easy to remove inspection covers and a conveniently located inspection window.

| Model | FM-3B3 Bucket elevator |

| Bucket Volume | 1.0L/1.8L/3.8L/6.5L |

| Machine Structure | Stainless steel or carbon steel |

| Production Capacity | 2-3.5m³/h / 4-6m³/h / 6.5-8m³/h / 8.5-12m³/h |

| Machine Height | 3296mm for standard (1.8L) |

| Discharging Height | 3256mm for standard (1.8L) |

| Hopper Material | Food grade PP, ABS, Stainless steel |

| Packing Size | 2050mmX1350mmX980mmfor standard (1.8L) |

| Voltage | AC220V or three phase 380V, 50hz/60hz |

| Power Supply | 0.75kw |

►The buckets are made of food grade reinforced polypropylene, molded in one piece and can handle temperatures from -10 to 60 degrees Fahrenheit.

►The vertical bucket elevator can be interface with different feeding devices because of its multiple feeding location.

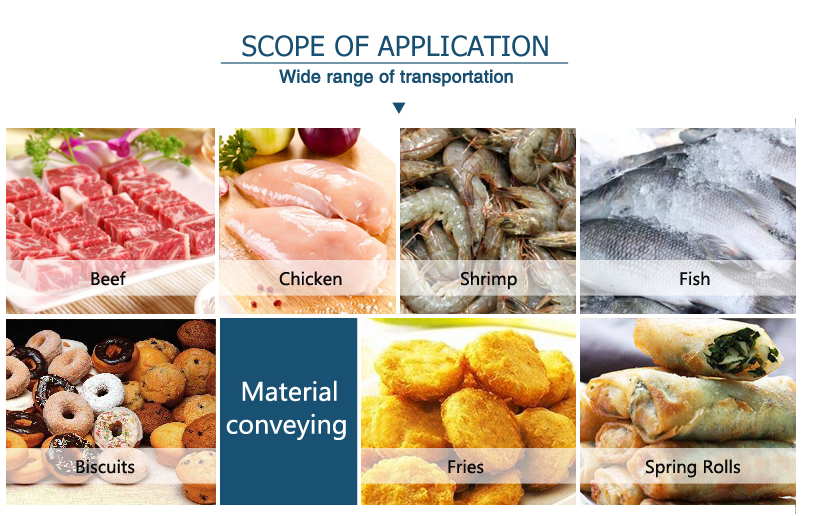

● Inclined belt conveyor

1.The conveyor belt is made of food grade PP material and made by mold method, with good appearance, not easily deformed, can bear high and low temperature.

2. The machine allows for controlled feeds at one or more locations and can easily interface with various types of feeding devices

3.The conveyors are easy to install and disassemble, and the belt can be washed by water directly.

2. The machine allows for controlled feeds at one or more locations and can easily interface with various types of feeding devices

3.The conveyors are easy to install and disassemble, and the belt can be washed by water directly.

● Inclined bowl conveyor

Inclined bowl conveyor

1. It can work with other equipment for continuous or intermittent type weighing and packaging line.

2.The bowl, made of 304 stainless steel material, is easy to disassemble and clean.

3.The stainless steel chain and machine frame makes it strong, durable and not easy to deform.

4.It can feed the material twice through flipping the switch and adjusting the timing sequence.

5.Speed is adjustable.

6.Keep the bowl straight without spilling the materials.

7.Can be combined with doypack filling machine, achieving the mixture of granule and liquid packing.

● Spiral screw conveyor

1. Worked with packaging machine for feeding variety of powdery products.

2. Two motors used for screw feeding and hopper vibrating, separately control.

3. To adjust the hopper amplitude according to the material characteristic.

4. The design of the separation between the hopper and auger screw makes the installation and disassembly easier.

5. Unique dust-proof design, keep the products clean and hygiene.

6. The auger screw has the forward and reverse function, which is easy to clean materials inside the auger screw.

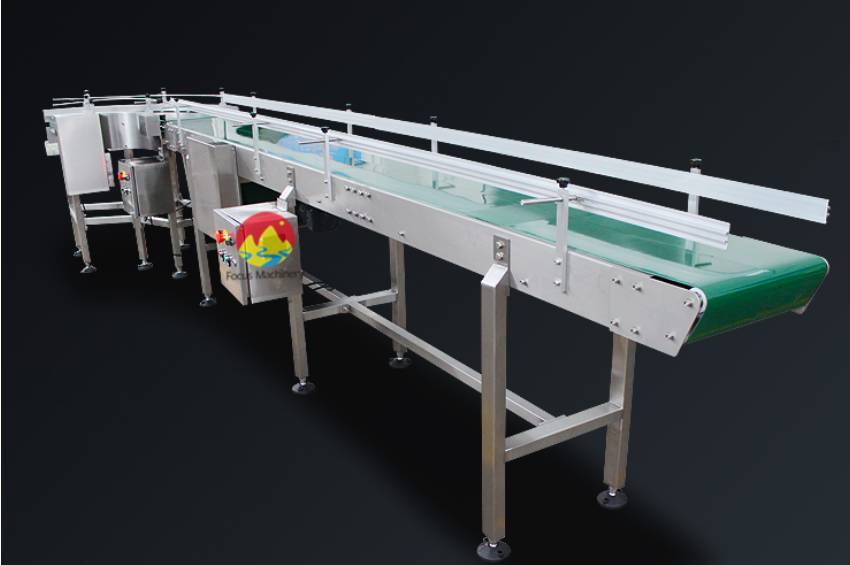

● Flat belt conveyor

1. This 90 conveyor 90 degree turn machine is made of food grade PP material .

2. This 90 degree conveyor belt is made by mold method, with good appearance, not easily deformed, can bear high and low temperature.

3. This conveyor belt 90 degree turn machine allows for controlled feeds at one or more locations and can easily intterface with various types of feeding devices.

4. This 90 degree belt conveyor are easy to install and disassemble, and the belt can be washed by water directly.

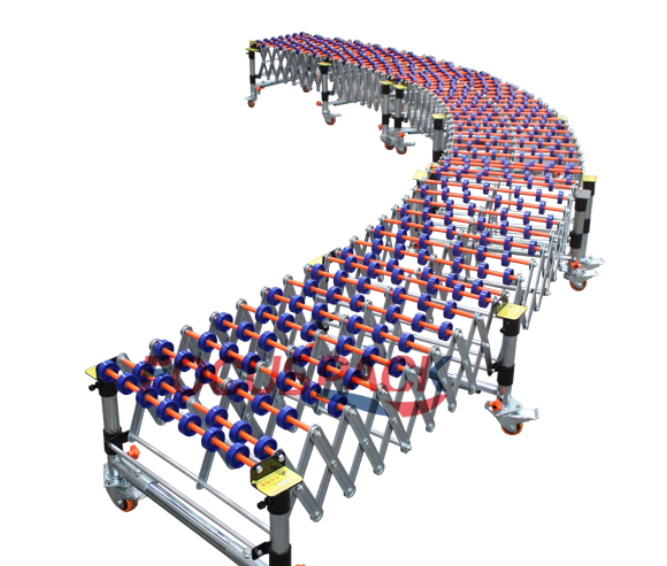

● Gravity conveyor

1. Self Tracking - Cartons follow the twists and turns of the conveyor path without using engineered curves.

2. Adjustable Height - Simply turn the locking knob to raise or lower the conveyor bed height.

3. Square Tubing Legs - Heavy duty legs for longer service life

4. Reinforced, ribbed zinc plated steel side plates. Assembled with bolts and lock nuts without rivets.

5. Structural Steel Support - Channel steel spans the entire conveyor width for unequalled strength.

6. Casters with brakes - 4'' or 5" swivel casters roll easily. Caster brakes lock both wheel and swivel simultaneously while the conveyor is in use.

7. Product Name: Flexible gravity skatewheel conveyor

→More article on Focusconveyor←

All You Need To Know About Conveyor System II