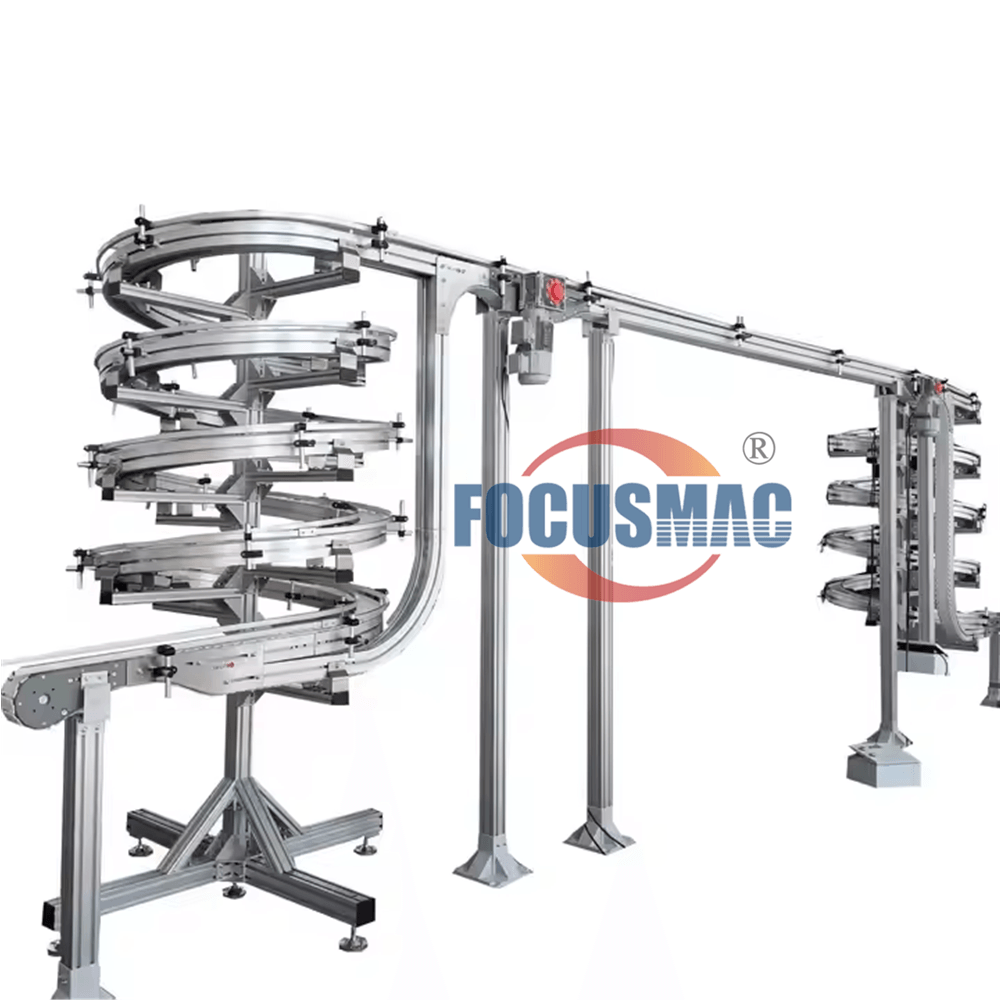

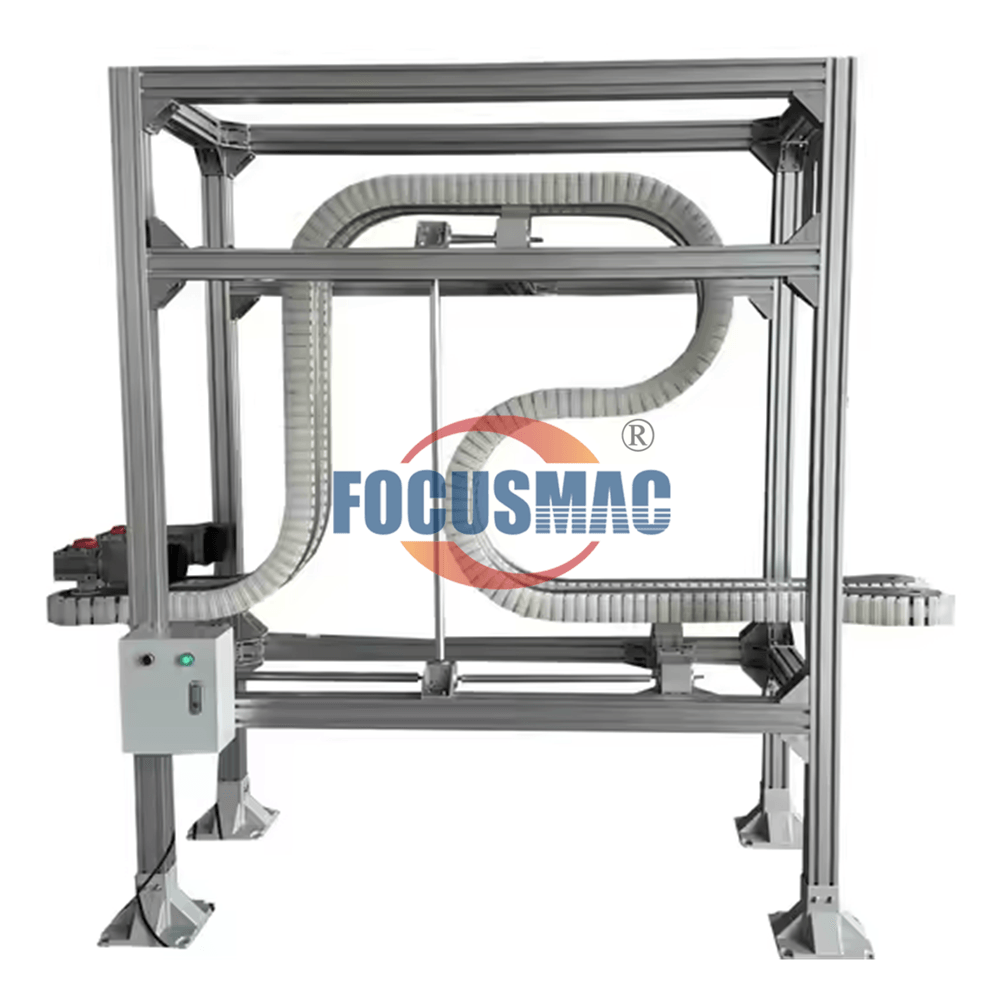

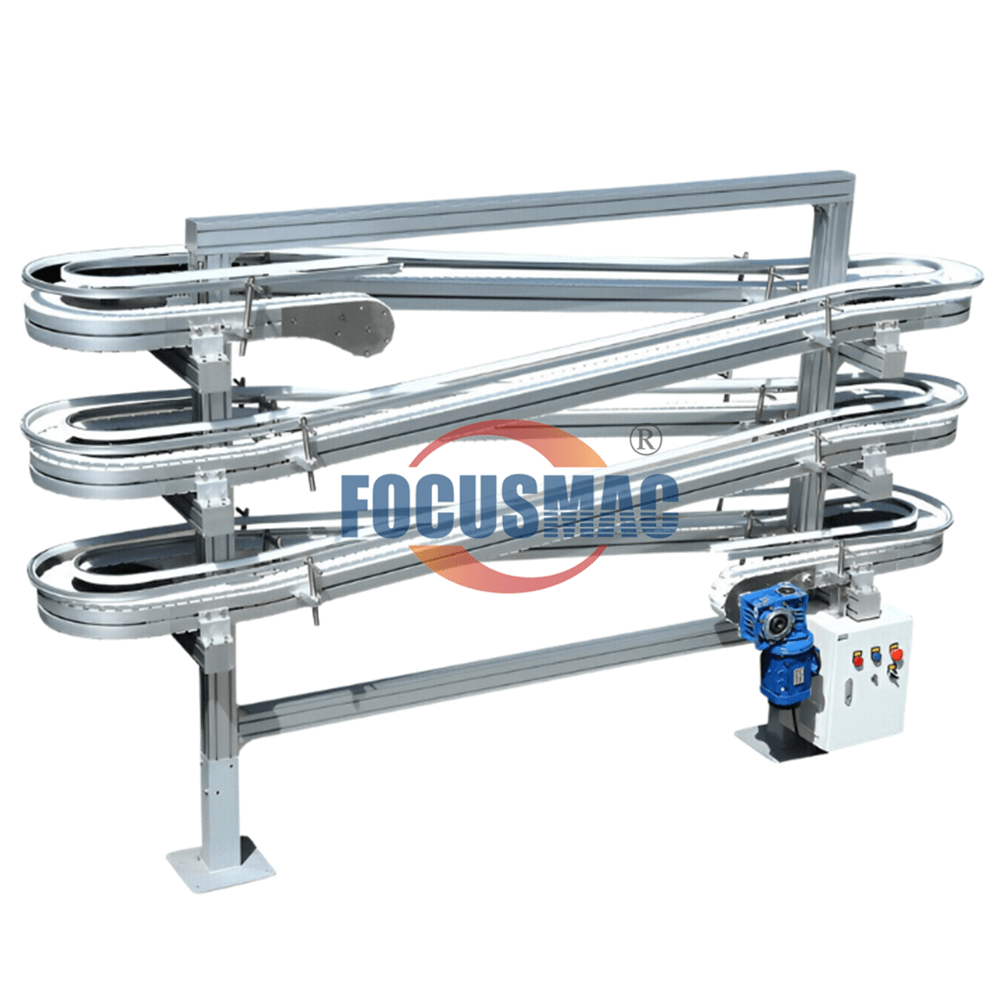

Upward Transport Flexible Chain Conveyor

Flexible Chain Conveyor (Plate Chain Conveyor) is suitable for heavy-duty conveying of irregular shaped products, it can meet the requirements of single-line conveying of beverage labeling, filling and cleaning equipment, and meet the requirements of large-scale feeding of sterilization machine, storage bottle and cold bottle machine. The head and tail of the two chain conveyors can be made into an overlapping mixed chain, so that the bottle (can) is in a dynamic excessive state...