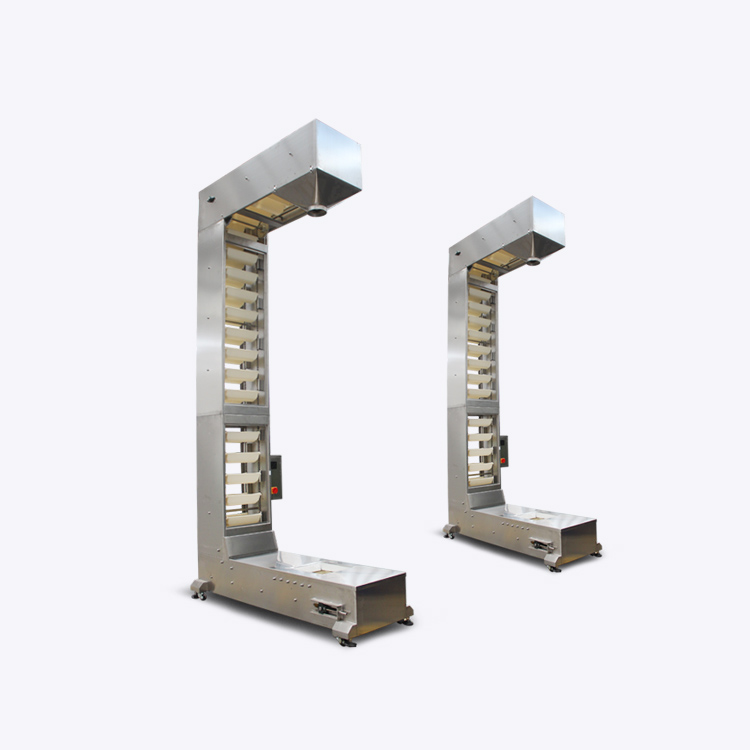

Bucket Elevator Conveyor Systems

In material handling, conveyor systems play a crucial role in moving goods and materials from one place to another. Bucket elevator conveyor systems are particularly useful for vertical or high-lift applications. They are widely used in industries such as agriculture, mining, and food processing. This article provides a comprehensive guide to bucket elevator conveyor systems, including their definition, types, advantages, applications, and maintenance tips.

What is a Bucket Elevator Conveyor System?

A bucket elevator conveyor system is a material handling system that moves materials in a vertical or high-lift application using buckets attached to a rotating chain or belt. The buckets are loaded with the material at the bottom of the elevator and are then lifted to the top of the elevator, where the material is unloaded.Types of Bucket Elevator Conveyor Systems

There are two main types of bucket elevator conveyor systems: continuous bucket elevators and centrifugal bucket elevators. Continuous bucket elevators are designed to handle fragile or friable materials and operate at a slower speed to minimize breakage. Centrifugal bucket elevators, on the other hand, are designed for heavy-duty applications and operate at a faster speed to handle larger volumes of materials.Applications of Bucket Elevator Conveyor Systems

Bucket elevator conveyor systems are widely used in a variety of industries, including:- Agriculture (for the handling of grain, seeds, and feed)

- Mining (for the handling of minerals, ores, and coal)

- Food processing (for the handling of cereals, nuts, and fruits)

- Pharmaceuticals (for the handling of powders and capsules)

- Chemicals (for the handling of fertilizers, salts, and acids)

- Construction (for the handling of cement, sand, and gravel)

Factors to Consider Before Selecting a Bucket Elevator Conveyor System

When selecting a bucket elevator conveyor system, several factors should be taken into consideration, including:- Material characteristics (e.g., size, density, and flowability)

- Capacity requirements

- Height and distance of the lift

- Environmental conditions (e.g., temperature and humidity)

- Power requirements

- Maintenance and operating costs

- Safety requirements

Installation and Maintenance of Bucket Elevator Conveyor Systems

Proper installation and maintenance are essential for the safe and efficient operation of bucket elevator conveyor systems. Here are some tips to ensure optimal performance:- Follow the manufacturer's installation and maintenance guidelines

- Regularly inspect the system for wear and tear, misalignment, and other issues

- Replace worn or damaged components promptly

- Lubricate moving parts regularly

- Keep the system clean and free of debris

- Train personnel on proper operating procedures and safety protocols